SR-71 S1030 Pressure Suit

The altitude and speed at which the SR-71 flew dictated the need for a full pressure suit: The SR-71 frequently flew at 85,000 or greater, and a Mach 3 cruise would cause the outer surface of the plane to heat to 400°F and the cockpit temperature to exceed 100°F. Since was necessary for pilots to fly for extended periods in their pressurized suit, designers over the years strove to improve pressure suit materials, processes, and technologies to maximize functionality and minimize suit-induced stress and fatigue on the pilot.

SR-71 pilots in front of their aircraft.

From page 344 (page 347 in the PDF) of Dressing

for Altitude: U.S. Aviation Pressure Suits-Wiley Post to Space

Shuttle.

Extraction by heroicrelics.

The pressure suit used would be an evolution of the suits used on several programs before it.

When the A-12 (a predecessor of the SR-71) program started, consideration was given to using the suit worn by U-2 pilots, but the cockpit heating issue led to the development of a new suit, which also had to protect the pilot from windblast should it become necessary to eject at supersonic speeds. These requirements led to the development of the S901 series of "Flying Outfit, Full-pressure, High Altitude, Multi-Layer" suits by the David Clark Company. The suit was fabricated in 12 sizes: small, medium, large, and extra large, with short, regular, and long versions of each, and could accommodate pilots ranging from 125 to 224 pounds and from 63 inches to 76 inches in height.

The S901H was the primary production suit for the A-12. It used a pressure-sealing zipper running from between the shoulder blades, down and under the buttocks, and terminating in the front at waist height. Original versions of the suit had an aluminized outer layer, but pilots complained that this created unwanted reflections inside the cockpit, so David Clark developed a white Dacron outer layer for later S901Hs; since Dacron was not fireproof, it was backed with HT-1 fabric.

After the Gary Powers U-2 incident, the U.S. pledged to terminate manned overflights of the Soviet Union, leading to the development of the unmanned D-21 unmanned drone project. These drones were intended to be launched from an M-21 mother craft, a derivative of the A-12. Unfortunately, launching the D-21 while the M-21 was traveling at Mach 3 was difficult, and on an early flight the D-21 crashed into the M-21 during launch, causing the latter to lose control and tumble toward the Pacific Ocean. While both pilots successfully ejected, one drowned when his pressure suit took on water. The suit was updated to include an automatic flotation-inflation device.

When the SR-71 program began, it was necessary to create a new S901 variant, the S901J, because the SR-71 used a different type of ejection seat than did the A-12. Among the differences were that the aircraft oxygen hoses no longer attached directly to the controller on the suit's abdomen; instead, two hoses ran from the aircraft to the right rear corner of the seat kit, which included an emergency oxygen supply. Oxygen lines with quick-disconnects then connected to the center rear of the helmet. The suit's neck ring was also based on a design developed for the Project Gemini spacesuit.

The S901J had a white Nomex exterior cover to provide thermal and physical protection for the restraint assembly. Openings allowed the parachute harness straps and other hardware to pass through the exterior cover. The cover also featured a variety of pockets and a flotation system. The floats were laced to the exterior cover around the neck area and passed under the arms and into pockets on the front of the exterior cover. The flotation system included a carbon dioxide cylinder with activating lanyard as well as an oral inflation tube.

Meanwhile, new versions of the U-2 aircraft introduced in 1967 necessitated changes to their pilots' pressure suits, and the S1010 was introduced. In general, the S1010 was similar to the S901J but with oxygen and electrical connections tailored for the cockpit of the U-2R, featuring a fully integrated parachute harness, an automatic water-activated flotation system, and a urine-collection system. A new, lighter-weight helmet was designed for it to minimize pilot fatigue during long missions.

Subsequent modifications of the S1010 introduced a separate harness which incorporated the parachute and flotation gear which worn over the suit. Later, another new helmet was introduced which provided freedom of head movement within the helmet (eliminating neck stress) and featuring a large visor with improved visibility.

In late 1978, SR-71's S901J pressure suit was replaced with the S1030. The S1030 continued to be a rear-entry suit and used a separate retainer assembly to contain an integrated parachute harness and a fully redundant, automatic flotation system that had improved cold-temperature performance and water-activated inflation devices. The S1030 also included the drinking port and urine-collection system and came in the 12 standard sizes, with eight sizes of bladder boots, 12 sizes of gloves, and a single helmet size with 3 cushion sizes. The color of cover layer was referred to as "old-gold" and was chosen to improve identification during search and rescue operations.

An S1030 pressure suit without retainer assembly.

Click image for additional information in a new window.

Photo courtesy Flight Test Historical Foundation.

A retainer assembly similar to that worn with the S1030 pressure suit.

Click image for additional information in a new window.

Photo courtesy Flight Test Historical Foundation.

In 1978, NASA contracted with the David Clark Company to develop the S1030A full pressure suit for use with the Space Shuttle program. During its initial R&D flights, the Shuttle would use SR-71 ejections seats.

Sources indicate that the S1030As were not "modifications" of the S1030 suit, but were new suits fabricated expressly for the Shuttle. They were derivatives of the S1030 design, using most of the same hardware and manufacturing techniques, but with different softgoods to support Shuttle requirements.

The S1030A consisted of a pressure suit, helmet, gloves, exterior cover, anti-G suit, and biomedical instrumentation system. The suit had increased proof-pressure requirements. NASA wanted the helmet microphoes to always be "hot" so the astronauts didn't need to key a transmit switch when they talked. Since hot mics tend to pick up breathing sounds, the David Clark Company installed cut-off switches which were tied to the oxygen regulator so that every time the pilot inhaled, the switches muted the microphone.

David Clark manufactured 13 S1030As, one certification suit and 12 for the Orbiter Flight Test program crews. NASA initially expected there to be six OFT missions, but eventually reduced this to four. After the flight test program concluded, several of the suits were returned to the Air Force, where hardware was stripped for use with standard S1030 suits, and the remainder of the suits were eventually scrapped.

David Clark continued to evolve their pressure suits, introducing the S1031 suit to replace the S1010 on the U-2; the suit was a variant of the S1030 with the changes necessary to mate with the U-2 interfaces and went into service in late 1982.

In 1991, the S1031C was introduced to replace both the S1030 in the SR-71 and the S1031 in the U-2. The S0131C accommodated the differences in aircraft by designing a parachute-harness/retainer assembly and urine-collection system that was reconfigurable in the field for use in either aircraft, although an aircraft-specific helmet was retained.

S1031 pressure suit with inflated flotation cells.

From page 346 (page 349 in the PDF) of Dressing

for Altitude: U.S. Aviation Pressure Suits-Wiley Post to Space

Shuttle.

Extraction by heroicrelics.

In late 1987 (i.e., before beginning development on the S1031C), the David Clark Company began developing a new suit to replace the S1030 and S1031, with a goal to develop a common suit that reduced crewmember stress and fatigue and to reduce ground support and maintenance requirements. This new S1034 was to be a "clean-sheet" design, rather than an evolution of previous suits, but ended up looking very much like an evolutionary suit. Designers identified several developments that might reduce stress and fatigue, including a lightweight helmet, breathable-gas-container materials, low-torque bearings, and a better glove-disconnect design.

Pilots evaluating the engineering model S1034 and found it lighter, less bulky, more comfortable, easier to don and doff, and more mobile than the S1030/S1031. In addition, it appeared to be easier to maintain.

The S0134 has gone on to replace the suits in both the SR-71 and U-2 programs, and is also used by NASA for its WB-57 flights.

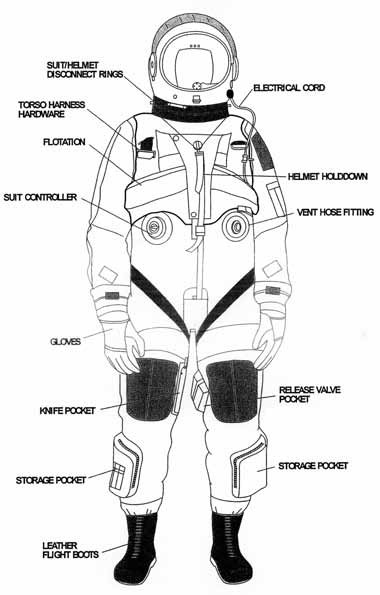

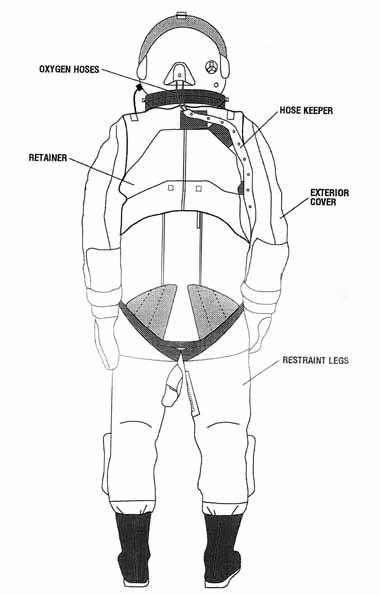

Diagram of S1034 pressure suit.

From page 351 (page 354 in the PDF) of Dressing

for Altitude: U.S. Aviation Pressure Suits-Wiley Post to Space

Shuttle.

Extraction by heroicrelics.

Callouts in these diagrams include

Front:

- Suit/helmet disconnect ring

- Electrical cord

- Torso harness hardware

- Flotation

- Helmet holddown

- Suit controller

- Vent host fitting

- Gloves

- Knife pocket

- Release valve pocket

- Storage pocket (2)

- Leather flight boots

Back:

- Oxygen hoses

- Hose keeper

- Retainer

- Exterior cover

- Restraint legs

The bulk of the descriptive text on this page was taken, largely verbatim, from Dressing for Altitude: U.S. Aviation Pressure Suits–Wiley Post to Space Shuttle.