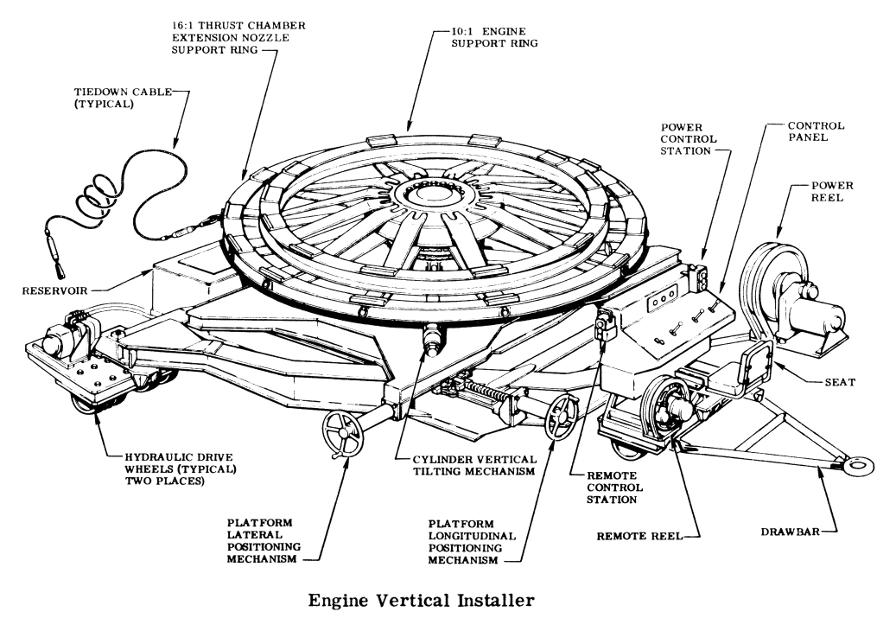

F-1 Rocket Engine G4049 Engine Vertical Installer

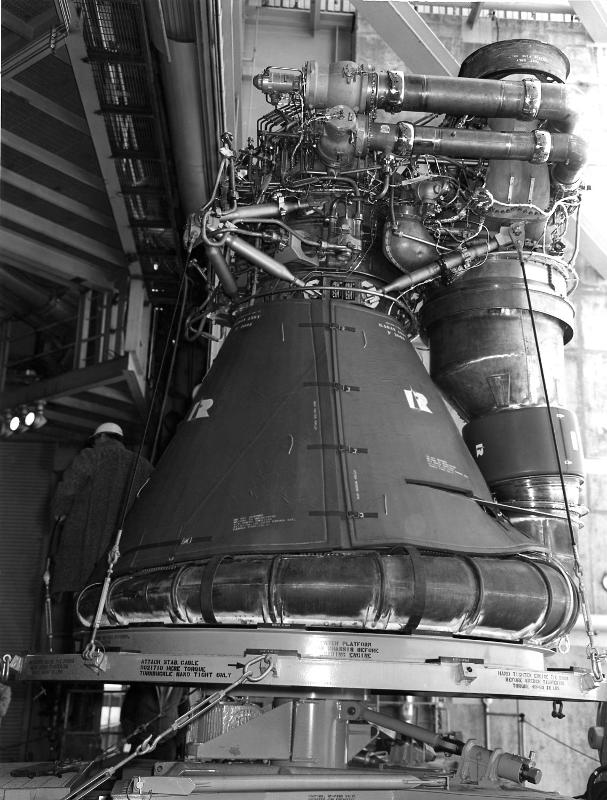

When the Saturn V S-IC (first) stages were manufactured at the Michoud Assembly Facility, their F-1 rocket engines were installed while the stages were in the horizontal position, using an engine horizontal installation tool and a facility hoist. However, whenever S-IC stages were shipped or delivered (other than from the VAB to the launch pad), the stages were transported without nozzle extensions installed on the F-1 engines; the nozzle extensions were installed while the stages were in the vertical position.

From time to time, it was also necessary to remove or install an F-1 engine on an S-IC which was in the vertical position. Although this was an unusual event for most stages, the S-IC-T stage (the static test stage, used to static test the S-IC stage and its five F-1 engines in Marshall Space Flight Center's S-IC test stand) was delivered to the test stand without engines. Engines were installed while the S-IC-T stage was installed vertically in the test stand. Engines were also swapped out and moved from one position to another at various times throughout the static test program.

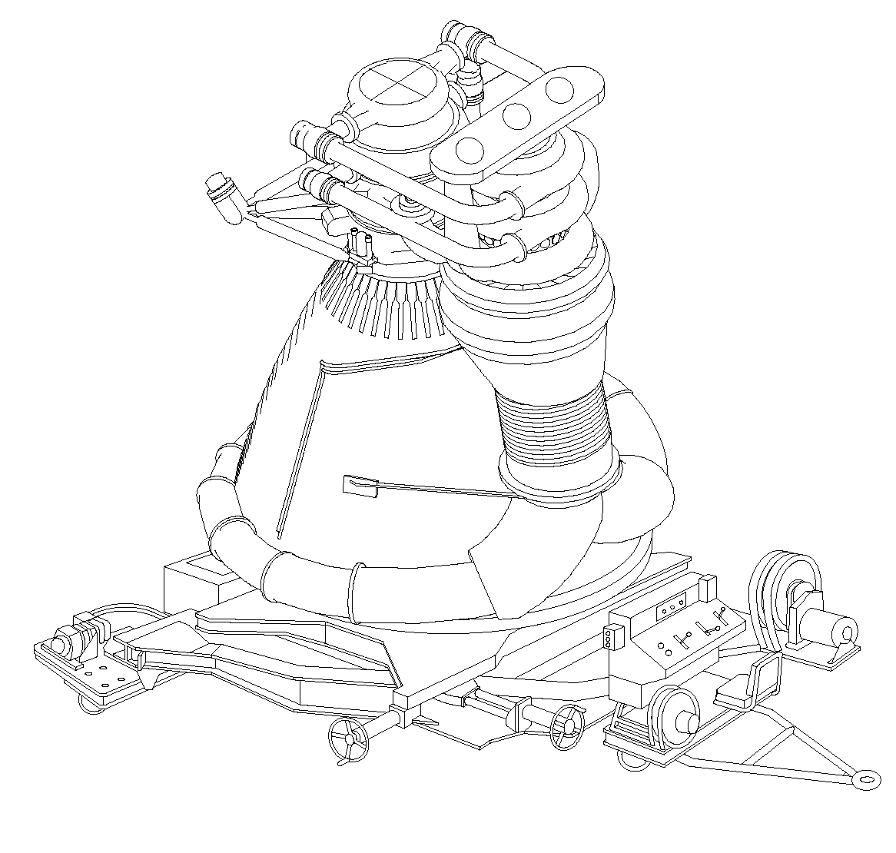

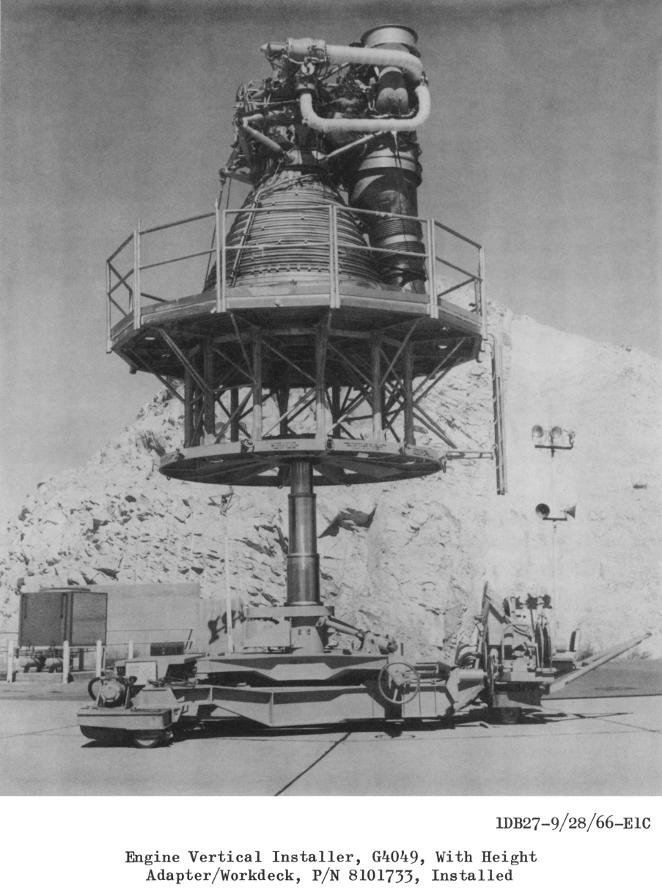

The G4049 Engine Vertical Installer was used to install nozzle extensions and F-1 engines when an S-IC stage was in the vertical position.

Click image for a 2075x1461 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

The F-1 engine was placed on the installer, which was used to position the engine vertically and horizontally and to raise the engine to the facility attach point.

Click image for a 1166x1110 pixel version of this image in a new window.

From page 49 (p. 50 in the PDF) of the "Data Pages" of the Marshall Space Flight Center

F-1 Engine Static Test Stand entry on the Historic American

Building Survey/Historic American Engineering Record.

Extraction from an advance review copy and cleanup by heroicrelics.

As described in various Saturn V ground support equipment-related documentation, the engine vertical installer was an electrohydraulic-operated, self-propelled, lifting and positioning unit for the engine. The vertical installer consisted of a dual-pressure hydraulic system, electrical system, control console, manually-operated tilting mechanism, manually-operated horizontal positioning mechanism, a hydraulically-operated azimuth drive, a pair of hydraulically-operated drive wheels and gearboxes, and a three-stage lifting cylinder, all supported on a triangular frame. Twelve wheels, including the hydraulic drive wheels, supported the vehicle frame. It also had an attachable tow bar. The vertical installer platform or cylinder could be operated manually with control valves on the control panel, or remotely using the remote-control station. The drive wheels could be operated from the control panel only.

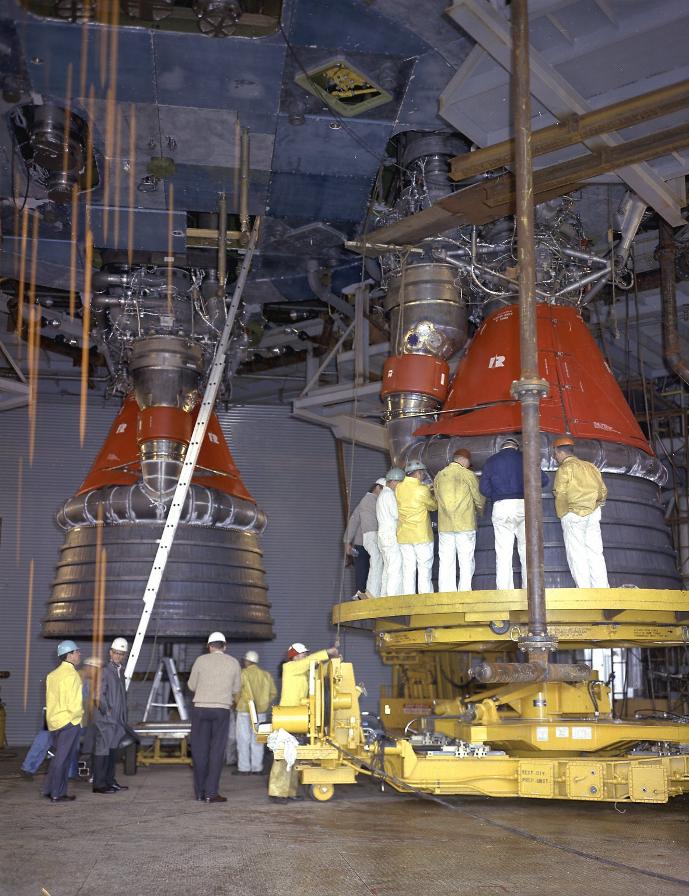

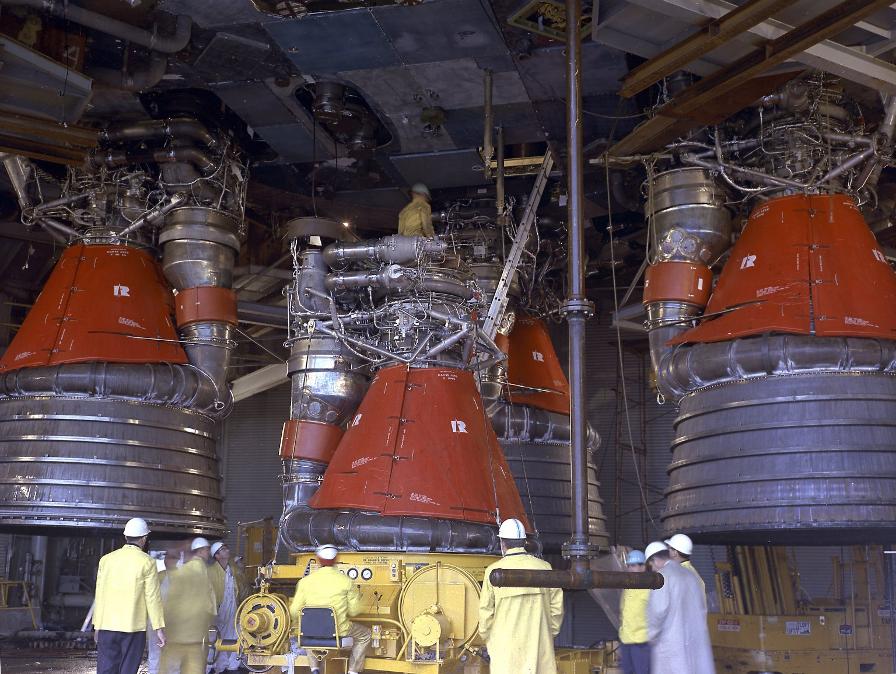

Here is a series of photos showing the engine vertical installer being put through its paces:

Click image for a 2816x2136 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

Click image for a 2805x2172 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

Click image for a 3614x4893 pixel version of this image in a new window.

From page A-44 of the Final Report, F-1 Engine Qualification Test

Program, located in the Thompson collection of the archives of the University of Alabama

at Huntsville.

Scan and cleanup by heroicrelics.

Here are three photos of the engine vertical installer being used to position F-1 engines for installation of the S-IC-T stage. The first photo is undated; while I don't know whether it is of an engine which was initially installed in the stage or whether it is from an engine swap, it appears to show the engine on the periphery of the test stand deck, rather than directly under the stage.

Also note that the two color photos are dated March 1, 1965. While the S-IC-T stage was first installed in the test stand on March 1, the engines were not actually installed in the stage until March 27 through 30.

Click image for a 1137x1498 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

Click image to open its page at archive.org's NASA Image collection in a new window.

Click image to open its page at archive.org's NASA Image collection in a new window.

Vince Wheelock, a Rocketdyne veteran, recalls there being six engine vertical installers in the Saturn V program. He didn't elaborate, but it would seem that there was at least two at Marshall (one on the S-IC Test stand and one one the F-1 Test Stand) and at least one each at Kennedy Space Center and the Mississippi Test Facility (which has been renamed to the Stennis Space Center). I further speculate that there may have been one at the Air Force Research Laboratory at Edwards Air Force Base.

The F-1 Rocket Engine Technical Manual: Engine Data describes how the vertical engine installer was used to install nozzle extensions when an S-IC stage was installed in the test stand at the Mississippi Test Facility (MTF):

The nozzle extensions, slave hardware, and MTF static test instrumentation are installed on the engines after the stage is installed in the test stand and after receiving inspection. Using Engine Handler Sling G4052 and overhead cranes, the nozzle extension is removed from the barge and from Nozzle Extension Handling Fixture G4080 and Handling Adapter G4081 and placed on Engine Vertical Installer G4049 on the lower stand work platform. The installer, with nozzle extension, is positioned below the engine; then the nozzle extension is installed on the engine, and the installer lowered.

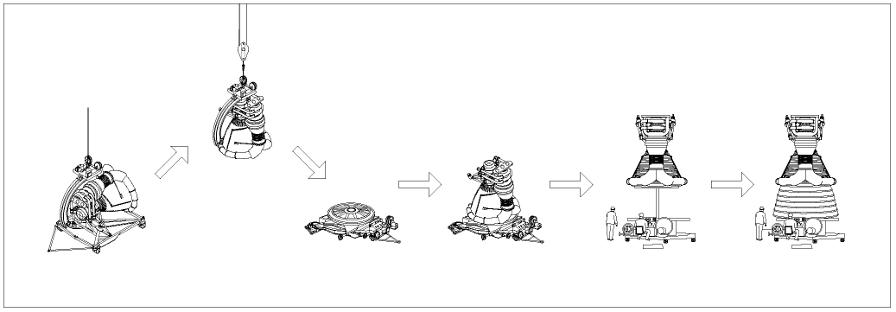

This diagram illustrates an F-1 engine, in an Engine Rotating Sling G4050, being rotated from horizontal to vertical position, being placed on the G4049 Engine Vertical Installer, and raised into position. The last panel of the diagram shows the nozzle extension being installed.

Click image for a 2074x722 pixel version of this image in a new window.

From page 50 (p. 51 in the PDF) of the "Data Pages" of the Marshall Space Flight Center

F-1 Engine Static Test Stand entry on the Historic American

Building Survey/Historic American Engineering Record.

Extraction from an advance review copy and cleanup by heroicrelics.

For a more detailed description of how an F-1 engine was installed in the F-1 Engine Test Stand at Marshall Space Flight Center, see my F-1 Test Stand Load and Test page.

Here are two photos of the KSC installer. Note this installer rides on air bearings, rather than casters, for more precise movement and more clearance.

Click image for a 2516x1960 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

Click image for a 2821x2193 pixel version of this image in a new window.

Photo courtesy Vince Wheelock.

Cleanup by heroicrelics.

For additional technical specifications of the installer during the F-1 era, see my G4049 Engine Vertical Installer data sheet.

Vince tells me that, after the Apollo program, the installers were all modified for use with the space shuttle main engine (SSME) program.

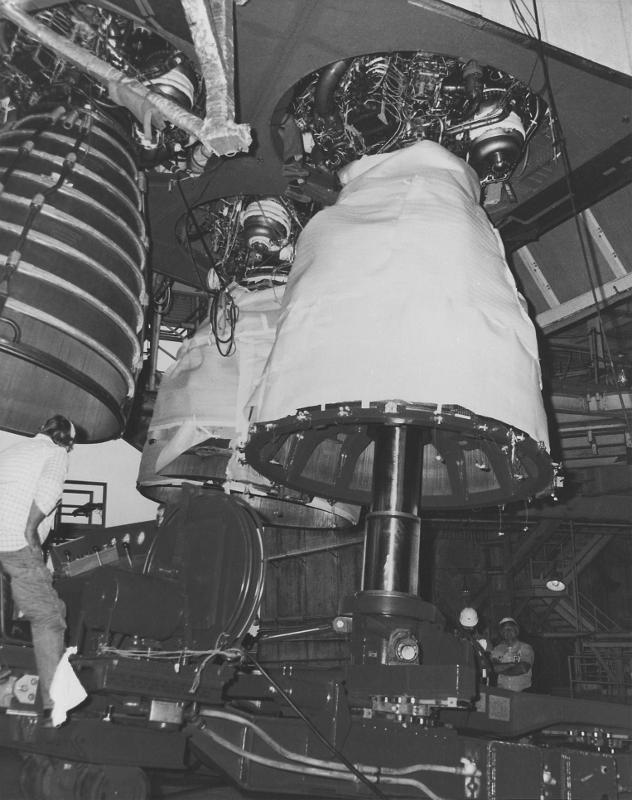

Here are two photos showing a converted installer being used to install a in the shuttle Main Propulsion Test Article at the National Space Technology Laboratories (formerly the Mississippi Test Facility [MTF] and today the Stennis Space Center).

Click image for a 1706x1087 pixel version of this image in a new window.

From page 7 of Main Propulsion Test

Article (MPTA).

Extraction and reconstruction by heroicrelics.

Click image for a 1526x1932 pixel version of this image in a new window.

Scan courtesy Marshall Space Flight Center.

Cleanup by heroicrelics.

A former Stennis employee contacted me via the Website. He tells me that he spent a "good number of the years" on test stand A-2 working SSME test. He was unaware that the engine installers were reused from the F-1 timeframe. He says that the one on A-2 sits on a movable platform and tilts up to be able to match the angle of the stand. It has the extension probe that fits into the throat of an SSME to support the powerhead with the engine at a cant. The one that was on test stand A-1 didn’t have the extension probe since the engine was installed vertical and thus the weight was evenly loaded on the nozzle. At least one of them had the smaller diameter nozzle platform that was used with the low-ratio nozzles that were used on SSME in early testing.

It's interesting that he mentioned low-ratio nozzles, because I didn't think that the SSMEs, at least in the color photo above, looked quite right -- the nozzle looked too "skinny".

But the installers' work still isn't done: The installers at Stennis are now being used in support of the J-2X program. I emailed William D. Greene, the NASA engineer who writes the J-2X Blog, after finding his J-2X Progress: Road Trip, Baby! post which mentiones the installers. He, too, was unaware of the engine installers' heritage.

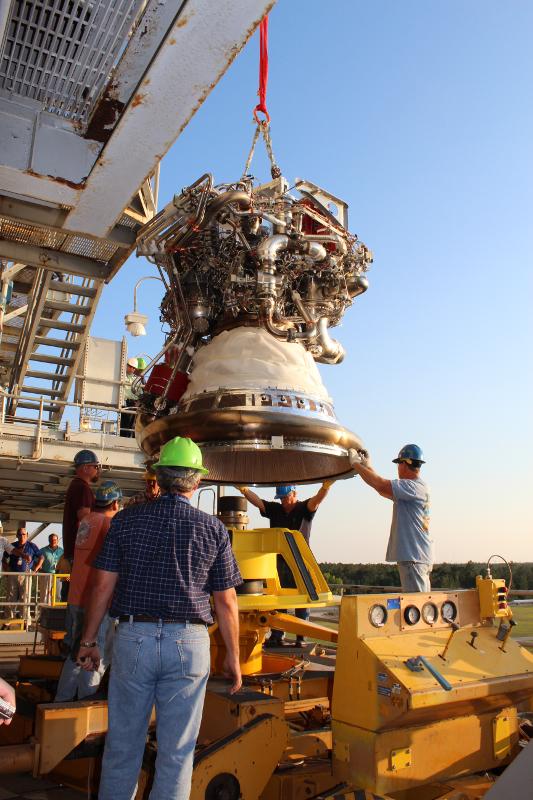

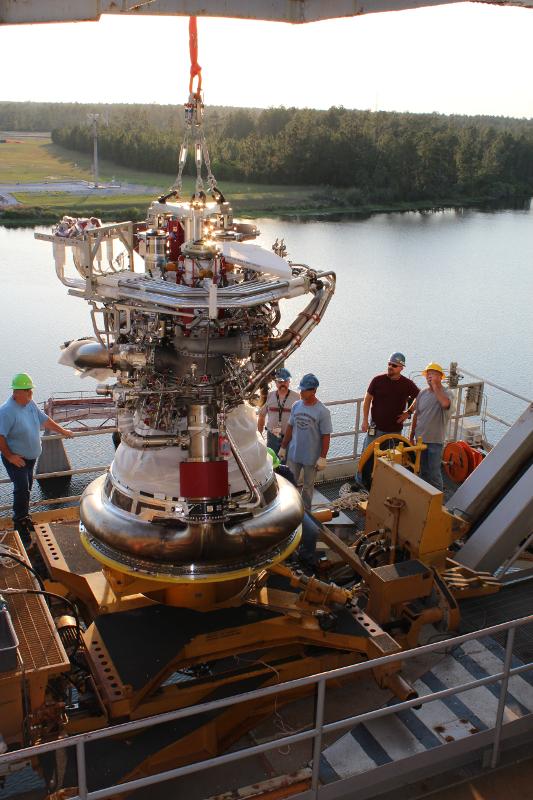

Greene was kind enough to send the following two photos showing the installers used to install J-2X engine 10001:

Click image for a 3456x5184 pixel version of this image in a new window.

Photo courtesy William D. Greene, Stennis Space Center.

Click image for a 3456x5184 pixel version of this image in a new window.

Photo courtesy William D. Greene, Stennis Space Center.

Another post on the J-2X blog also has some photos of an installer in use.

The former Stennis employee I mentioned above saw this blog post and pointed out that the table on the installer is a different color than the rest of the installer and speculates that they may have built a new table to match the J-2X geometry.

NASA in general and Stennis in particular have a number of additional photos showing the engine vertical installers being used in the J-2X program:

- J-2X Powerpack on the A-1 Test Stand

- J-2X Engine in A-2 Test Stand at Stennis

- SSC-2007-02820

- SSC-2011-00972

- SSC-2011-01846

- SSC-2011-02386

- SSC-2012-00278P

Finally, an interesting tidbit about terminology.

The official name of this device during the Saturn program was the "G4049 Engine Vertical Installer". When Vince Wheelock sent the photos, he referred to the equipment as both an "engine vertical installer" and a "VEI". I didn't think too much of it (the switched initials in the acronym), chalking it up to a bit of keyboard dyslexia (goodness knows that I suffer from that affliction!).

William Greene's blog referred to them as "EVI", but in his email reply he made reference to "EVI (or, as some call it, the VEI)." I thought this was interesting, so I asked him more about it. He said that "in any given meeting where the piece of equipment is a topic, either or both names are used."

Intrigued, I asked the former Stennis employee what he called it. He said that, on the test stands, they're just referred to as "the vertical installer."