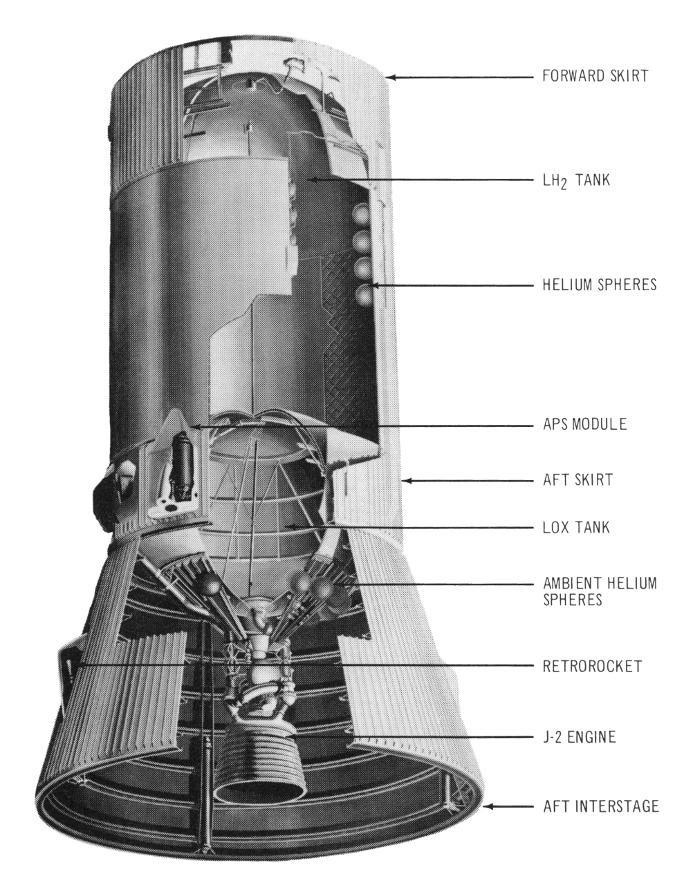

S-IVB (Saturn V) Overview

The S-IVB, the third stage of the Saturn V rocket, was the one of the largest liquid hydrogen stages produced in the 1960s. Equipped with one J-2 rocket engine, it produced about 225,000 pounds of thrust. It was 21 feet 8 inches in diameter and 58 feet 8 inches high.

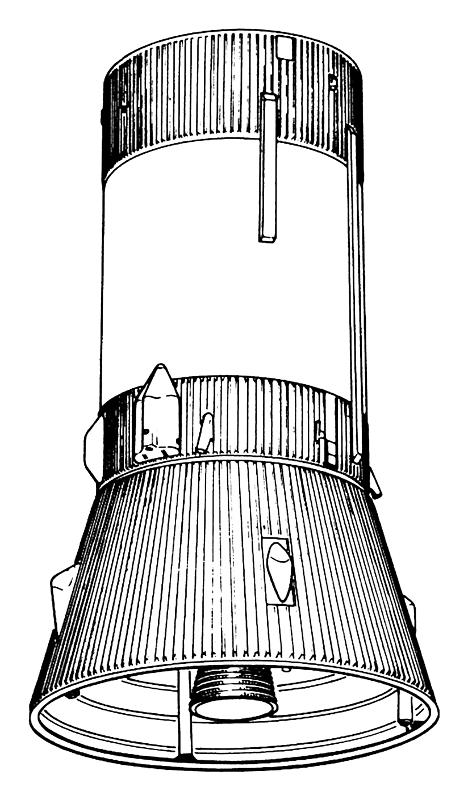

Click image for a 1652x2838 pixel version of this image in a new window.

From the front cover of the Saturn 503 Design Certification Review, S-IVB

Stage, located in the Thomson collection at the Dept. of Archives/Special

Collections, M. Louis Salmon Library, University of Alabama in

Huntsville.

Scan by heroicrelics.org.

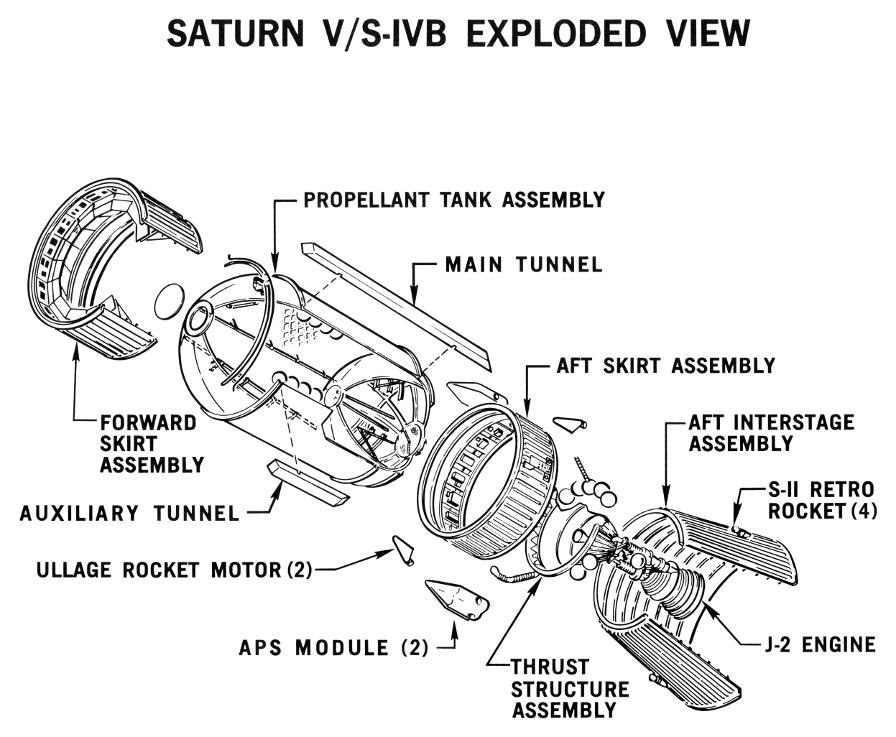

Structurally, the S-IVB stage consisted of

- An aft interstage, which mated the stage to the S-II second stage. Although I tend to associate the interstages with the lower stage, and the S-IVB aft interstage remained attached to the S-II stage, the interstage was properly part of the S-IVB.

- A cylindrical aft skirt, to which was connected the conical thrust structure. The engine was mounted to the thrust structure, which transmitted the thrust to the aft skirt, which in turn transmitted the thrust to the propellant tank walls.

- A liquid oxygen tank and a liquid hydrogen tank. Rather than each tank having customary hemispherical bulkheads at both ends (and separated by an intertank structure, as with the S-IC), the forward end of the LOX tank and the aft end of the LH2 tank were separated by a common bulkhead. The common bulkhead consisted of two aluminum domes forming the ends of the respective propellant containers separated by honeycomb insulation; the honeycomb insulation was necessary to prevent the LH2's -423° temperature from freezing the liquid oxygen.

- A cylindrical forward skirt, attached to the forward end of the LH2 tank, which transmitted the thrust loads to the Apollo payload. Range safety and telemetry antennas were mounted on the exterior of the forward skirt, and the interior of the forward skirt had cold plates to provide environmental conditioning for various electronic equipment also located on the walls of the forward skirt.

Click image for a 5351x4117 pixel version of this image in a new window.

From page 16 of the Saturn S-IVB Training Graphics: Systems

Familiarization, Saturn V (Revised October 1967), located in the Mauldin

collection at the Dept. of

Archives/Special Collections, M. Louis Salmon Library, University of

Alabama in Huntsville.

Scan and reconstruction by heroicrelics.org.

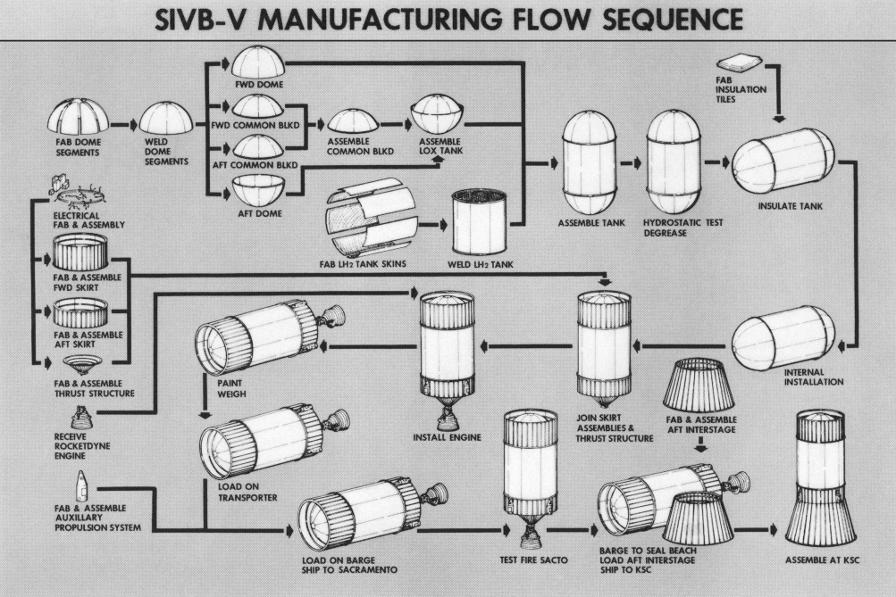

Having exploded the S-IVB stage in the diagram above, here we will put it back together in this manufacturing flow sequence diagram.

Click image for a 4015x2677 pixel version of this image in a new window.

Adapted from page 4 of the Saturn Third Stage, S-IVB

Manufacturing. Located in the Saturn V Collection, Dept. of Archives/Special

Collections, M. Louis Salmon Library, University of Alabama in

Huntsville.

Scan and adaptation by heroicrelics.org.

You might consider this a do-it-yourself guide, perhaps "how to build an S-IVB stage in 31 easy steps."

- Fabricate dome segments

- Weld dome segments

-

Repeat for each of

- Forward dome

- Forward common bulkhead

- Aft common bulkhead

- Aft dome

- Assemble common bulkhead

- Assemble LOX tank

- Fabricate LH2 tank skins

- Weld LH2 tank

- Assemble tank

- Hydrostatic test; degrease

- Fabricate insulation tiles

- Insulate tank

- Internal installation

- Electrical fabrication & installation

- Fabricate & assemble forward skirt

- Fabricate & assemble aft skirt

- Fabricate & assemble thrust structure

- Join skirt assemblies & thrust structure

- Receive Rocketdyne engine

- Install engine

- Paint; weigh

- Load on transporter

- Fabricate & assemble auxilliary propulsion system

- Load on barge; ship to Sacramento

- Test fire at SACTO

- Fabricate & assemble aft interstage

- Barge to Seal Beach; load aft interstage; ship to KSC

- Assemble at KSC

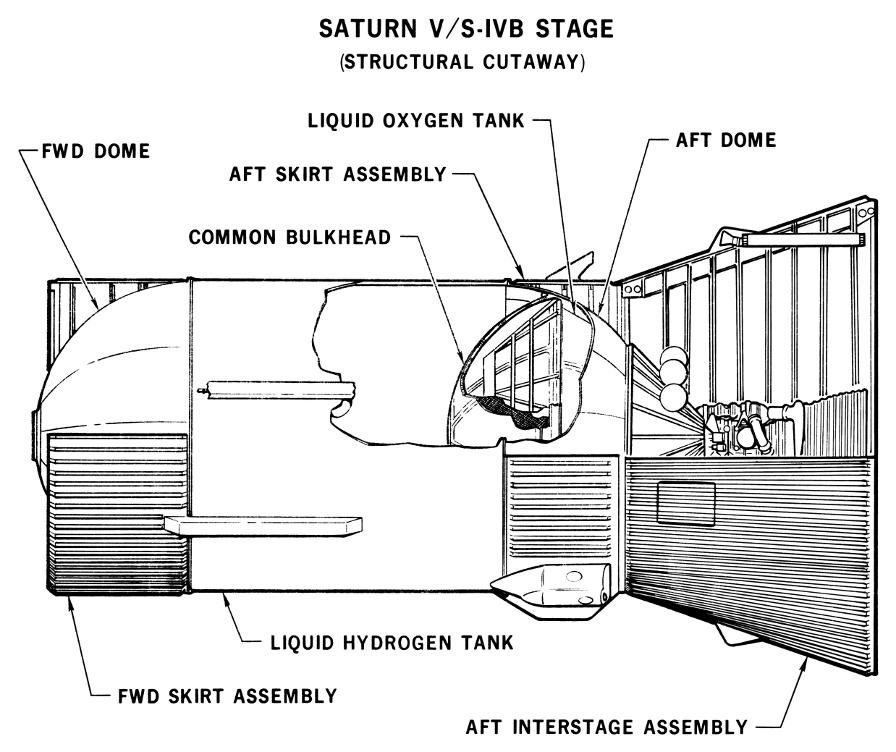

This cut-away diagram shows the major structural elements assembled into the final stage.

Click image for a 1618x1960 pixel version of this image in a new window.

From page 15 of the Saturn S-IVB Training Graphics: Systems

Familiarization, Saturn V (Revised October 1967), located in the Mauldin

collection at the Dept. of

Archives/Special Collections, M. Louis Salmon Library, University of

Alabama in Huntsville.

Scan and restoration by heroicrelics.org.

Another cut-away diagram showing the major structural elements assembled into the final stage, while at the same time showing the interior of stage subassemblies:

Click image for a 2005x2594 pixel version of this image in a new window.

From an unnumbered page at the beginning of Section 5 of the Saturn V

News Reference, located in the Dept. of Archives/Special

Collections, M. Louis Salmon Library, University of Alabama in Huntsville.

Also available on the mirror as a 4.1

megabyte PDF.

Scan by heroicrelics.org.

Note the ambient helium spheres, used by the propellant pressurization system.