S-II Stage Handling Ground Support Equipment

The Saturn V S-II (second) stage was a very light-weight rocket stage due to the environment in which it was designed: As the weight of the Apollo spacecraft increased, there was pressure to decrease the weight of the Saturn V rocket to compensate. To add another pound of payload required cutting 14 pounds from the S-IC, four to five pounds from the S-II, or one pound from the S-IVB. The S-IVB stage was already in production for the Saturn IB series of launchers, so it was too late in the process to make significant weight reductions. Removing 14 pounds from the S-IC for each pound of additional spacecraft weight wasn't feasible, so this meant that the brunt of the weight reduction fell to S-II stage, and it became a thin-shelled, delicate vehicle.

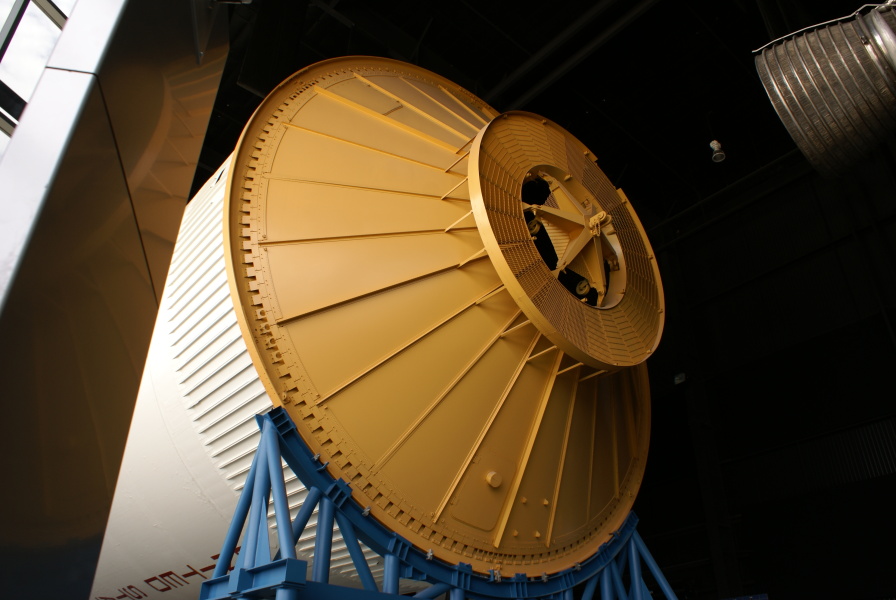

The S-II had a number of pieces of ground support equipment to ensure its safety during transportation and handling, attached to both its forward and aft ends. At the forward end are the yellow stage erecting sling, forward hoisting frame, and forward support ring, and at its aft are the silver static firing skirt and aft support ring:

NASA photo MSFC-6761059

Click image for additional information about this photo at the Internet Archive.

S-II Stage Forward End Ground Support Equipment

The stage forward end ground support equipment, although appearing as a single assembly, is actually three (or perhaps four) separate pieces of GSE: The forward support ring, the forward hoisting frame, and the stage erecting sling. One piece of equipment for which I could find no documentation is the doughnut-shaped work platform at the forward-most point of the assembly, although this work platform appears all of the vintage photos I found depicting the forward hoisting frame and related equipment. I'm not certain whether it was a separate piece of GSE or whether the documentation to which I have access was produced before the work platform was added to the forward hoisting frame.

Click image for more information about this picture; opens in a new window.

From my S-II (Davidson Center) picture set

at the U.S. Space & Rocket

Center.

Picture by heroicrelics.org.

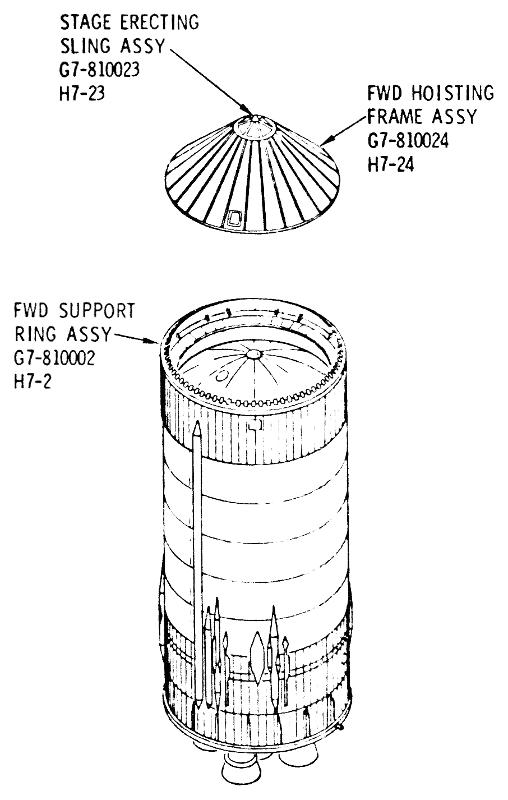

Here's an exploded-view diagram of the stage forward end GSE:

Click image for a 906x1426 pixel version of this image in a new window.

Adapted from page 1-66 of the Manufacturing

Plan for Saturn S-II, Stages 16-25, located in the Saturn V

collection of the archives of the

University of Alabama in Huntsville.

Extraction, cleanup, and adaptation by heroicrelics.org.

The S-II stages at Johnson Space Center and the U.S. Space & Rocket Center are displayed with the entire set of stage forward end handling GSE, but the S-II stage at Kennedy Space Center is displayed with only its forward support ring.

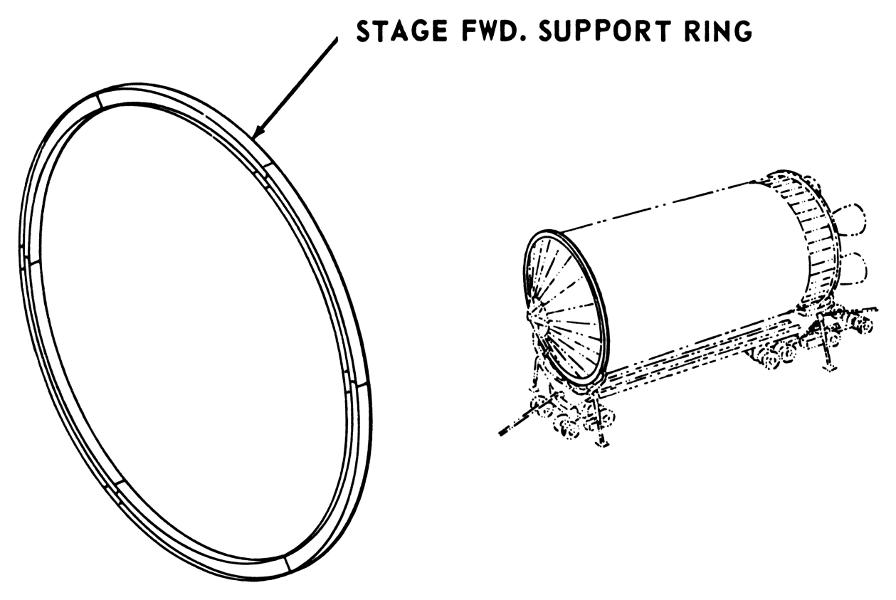

Forward Support Ring

The forward support ring provided the means for attaching forward hoisting equipment to the stage, and also provided forward support for the stage during transportation and horizontal handling operations. The ring was constructed from six welded I-beam segments which, when assembled, formed a ring approximately 33 feet in diameter and weighing approximately 4,000 pounds.

Click image for a 2519x1685 pixel version of this image in a new window.

Adapted from page 5-26 of the Saturn

V Launch Vehicle Ground Support Equipment Fact Booklet

(MSFC-MAN-100), located in the Saturn V collection of the archives of the University of Alabama

in Huntsville.

Scan, restoration, and adaptation by heroicrelics.org.

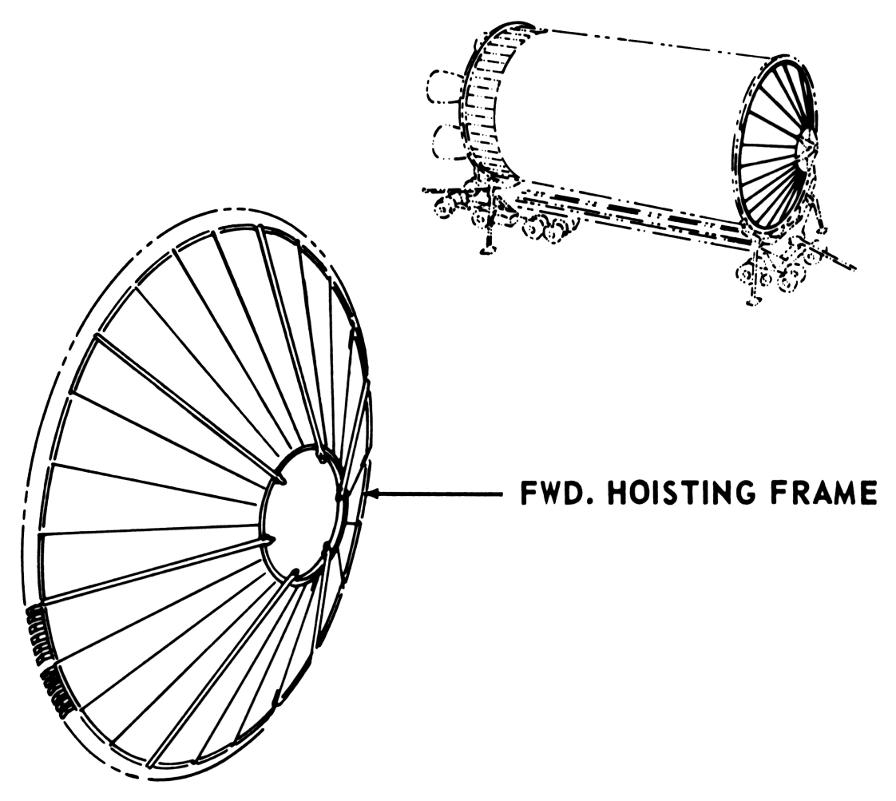

Forward Hoisting Frame

The forward hoisting frame transmitted the diametrical load of the stage erecting sling during all phases of hoisting operations. The frame was a cone-shaped structure tapering from approximately 33 feet at the outer diameter to approximately 10 feet at the inner diameter. It weighed approximately 3,700 pounds. On the base of the forward hoisting fame were 144 mounting flanges used for installing the frame to the forward support ring. The stage erecting sling attachments were provided by six hoist fitting equally spaced around the inner circumference of the hoisting frame cone neck. The forward hoisting frame was spliced in 12 segments to permit disassembly for transport or storage.

Click image for a 2244x2007 pixel version of this image in a new window.

Adapted from page 5-31 of the Saturn

V Launch Vehicle Ground Support Equipment Fact Booklet

(MSFC-MAN-100), located in the Saturn V collection of the archives of the University of Alabama

in Huntsville.

Scan, cleanup, and adaptation by heroicrelics.org.

Each of the 12 segments comprising the forward hoisting frame were numbered, as shown in this vintage photo of an S-II stage being delivered to the Vehicle Assembly Building at KSC:

NASA photo KSC-70P-19

Click image for additional information about this photo at the Apollo Lunar Surface

Journal.

Oddly, the S-II stage at JSC lacks the ladder at the 1:00 position.

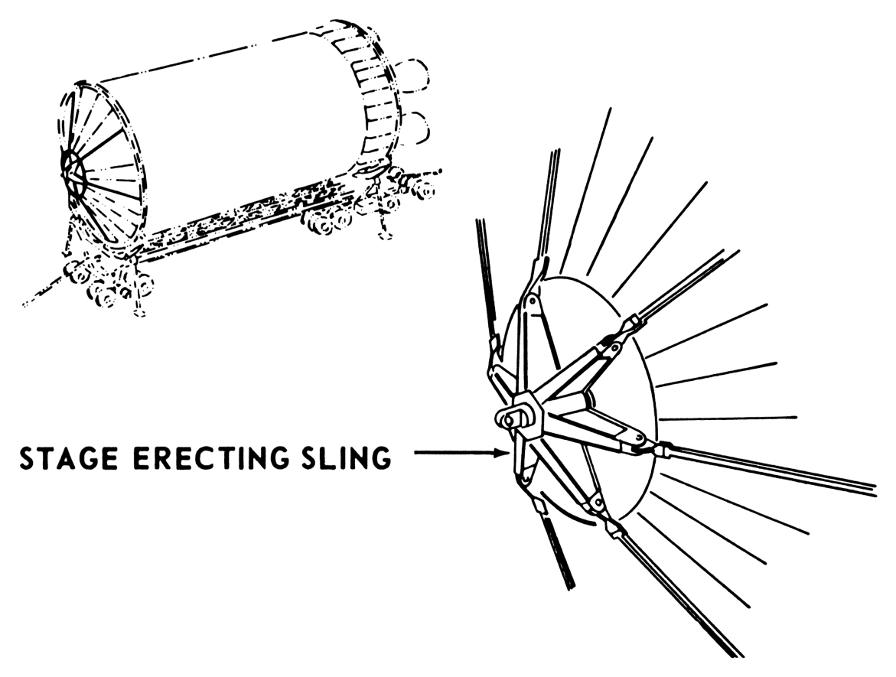

Stage Erecting Sling

The stage erecting sling transferred the stage weight from the forward hoisting frame to the crane hook to provide the forward lift point for stage hoisting operations. In addition, the sling was used to install or remove the forward support ring and forward support frame. The stage erecting sling incorporated six arms, equally spaced, which extended outward from a central plate, with a clevis on each arm. Each arm was identified by number and corresponded to the related hoisting frame segment. The clevises were joined to the forward hosting frame by six attaching pins. The central plate attached to a crane hook through an adapter and double shackle assembly. The sling weighed approximately 2,400 pounds.

Click image for a 2342x1771 pixel version of this image in a new window.

Adapted from page 5-30 of the Saturn

V Launch Vehicle Ground Support Equipment Fact Booklet

(MSFC-MAN-100), located in the Saturn V collection of the archives of the University of Alabama

in Huntsville.

Scan, restoration, and adaptation by heroicrelics.org.

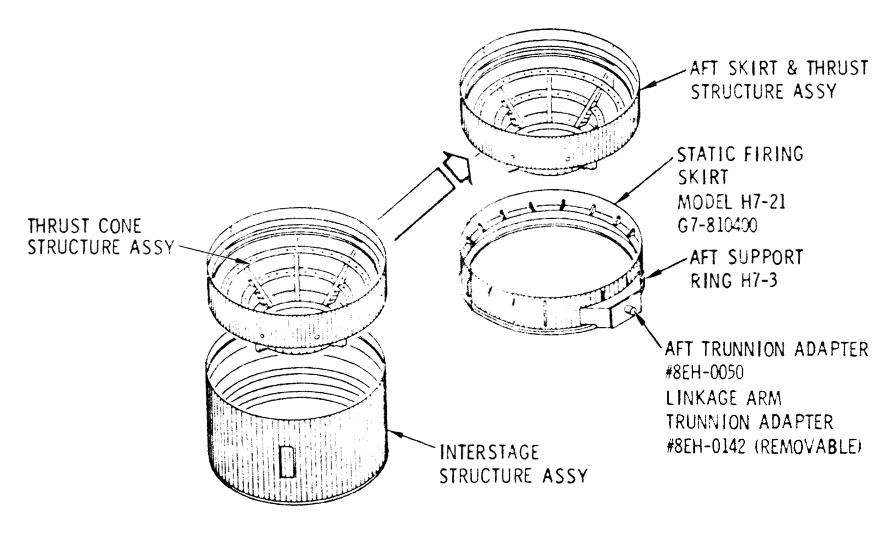

S-II Stage Aft End Ground Support Equipment

As with the stage forward end ground support equipment, the stage aft end ground support equipment appears to be a single assembly but is actually comprised of separate components: The static firing skirt and the aft support ring.

This exploded-view diagram shows the S-II's aft skirt and thrust structure, which is almost always attached either to the static firing skirt or the interstage (the latter during erection and mating in the VAB). In addition to the aft support ring installed on the static firing skirt, it also shows an aft trunion adapter (used to invert the stage for LH2 tank cleaning) attached to the static firing skirt:

Click image for a 1626x969 pixel version of this image in a new window.

Adapted from page 1-66 of the Manufacturing

Plan for Saturn S-II, Stages 16-25, located in the Saturn V

collection of the archives of the

University of Alabama in Huntsville.

Extraction, cleanup, and adaptation by heroicrelics.org.

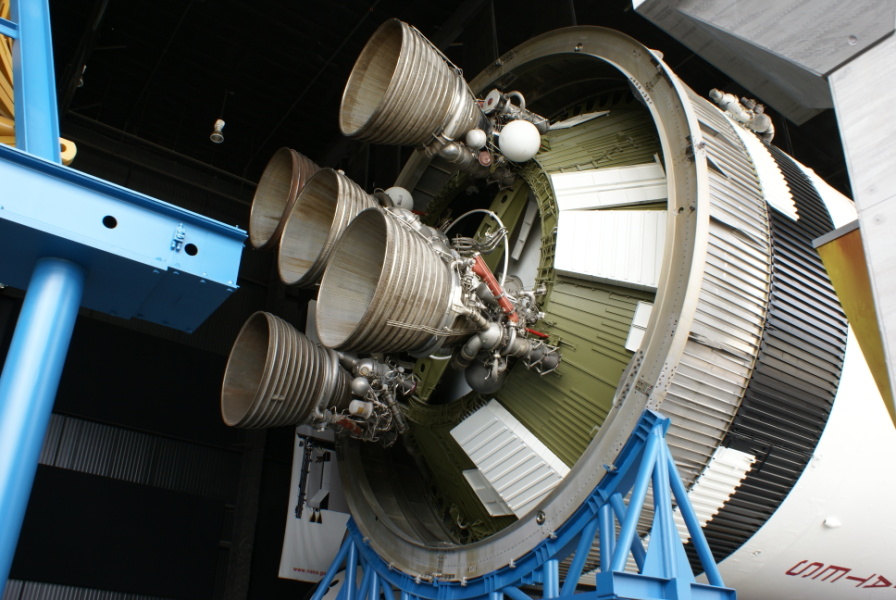

The KSC and JSC S-IIs are displayed without their aft stage handling GSE, with only the S-II stage at the USSRC displayed with its static firing skirt and aft support ring:

Click image for more information about this picture; opens in a new window.

From my S-II (Davidson Center) picture set

at the U.S. Space & Rocket

Center.

Picture by heroicrelics.org.

The name "static firing skirt" is a bit of a misnomer, as this skirt was attached to the stage during nearly all phases of ground handling after stage manufacturing was complete. For example, this vintage photo shows an S-II stage being off-loaded from a barge after arriving at the KSC turning basin, with the static firing skirt attached (and an engine protective frame installed aft of the skirt):

NASA photo 70-H-78

Click image for the full-sized version of this photo, formerly available at

the Apollo Lunar Surface

Journal (there appears to be no information regarding this photo on the

ALSJ, and indeed I can no longer find it on that Website).

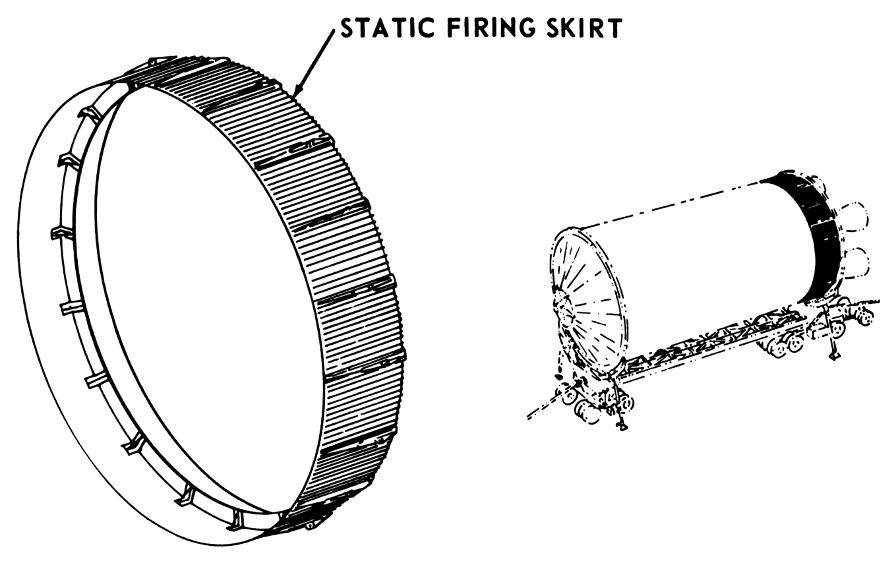

Static Firing Skirt

The static firing skirt provided a temporary structural medium between the stage and the aft support ring. It was used in conjunction with the aft support ring to make the connection and tiedown for static firings, and transmitted the thrust loads through the aft support ring to the static firing stand. The skirt was fitted with internal and external lift points to facilitate handling. It was cylindrically shaped, approximately six feet long 33 feet in diameter, and weighed approximately 13,500 pounds.

Click image for a 2719x1708 pixel version of this image in a new window.

Adapted from page 5-30 of the Saturn

V Launch Vehicle Ground Support Equipment Fact Booklet

(MSFC-MAN-100), located in the Saturn V collection of the archives of the University of Alabama

in Huntsville.

Scan, restoration, and adaptation by heroicrelics.org.

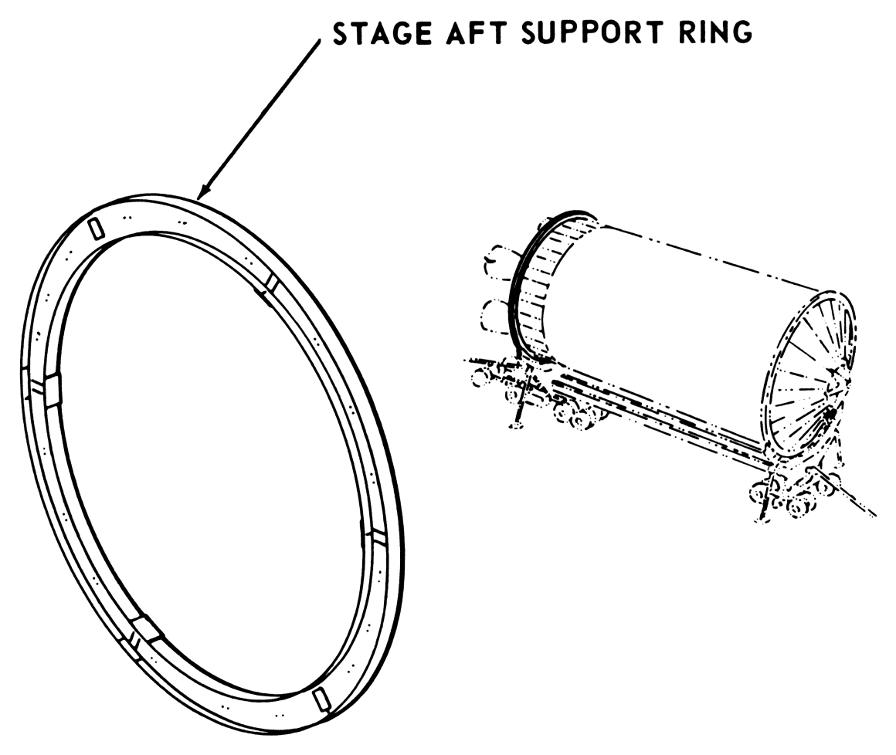

Aft Support Ring

The aft support ring provided the means for attachment of the aft hoisting frame for stage erecting or lowering procedures. The ring was constructed from six welded I-beam segments which, when assembled, formed a ring approximately 33 feet in diameter and weighed approximately 6,700 pounds.

Click image for a 2321x1956 pixel version of this image in a new window.

Adapted from page 5-26 of the Saturn

V Launch Vehicle Ground Support Equipment Fact Booklet

(MSFC-MAN-100), located in the Saturn V collection of the archives of the University of Alabama

in Huntsville.

Scan, restoration, and adaptation by heroicrelics.org.

The bulk of the GSE descriptive text on this page was taken, most of it nearly verbatim, from the Manufacturing Plan for Saturn S-II, Stages 16-25.